Research and Innovation are our corporate values

Find out more

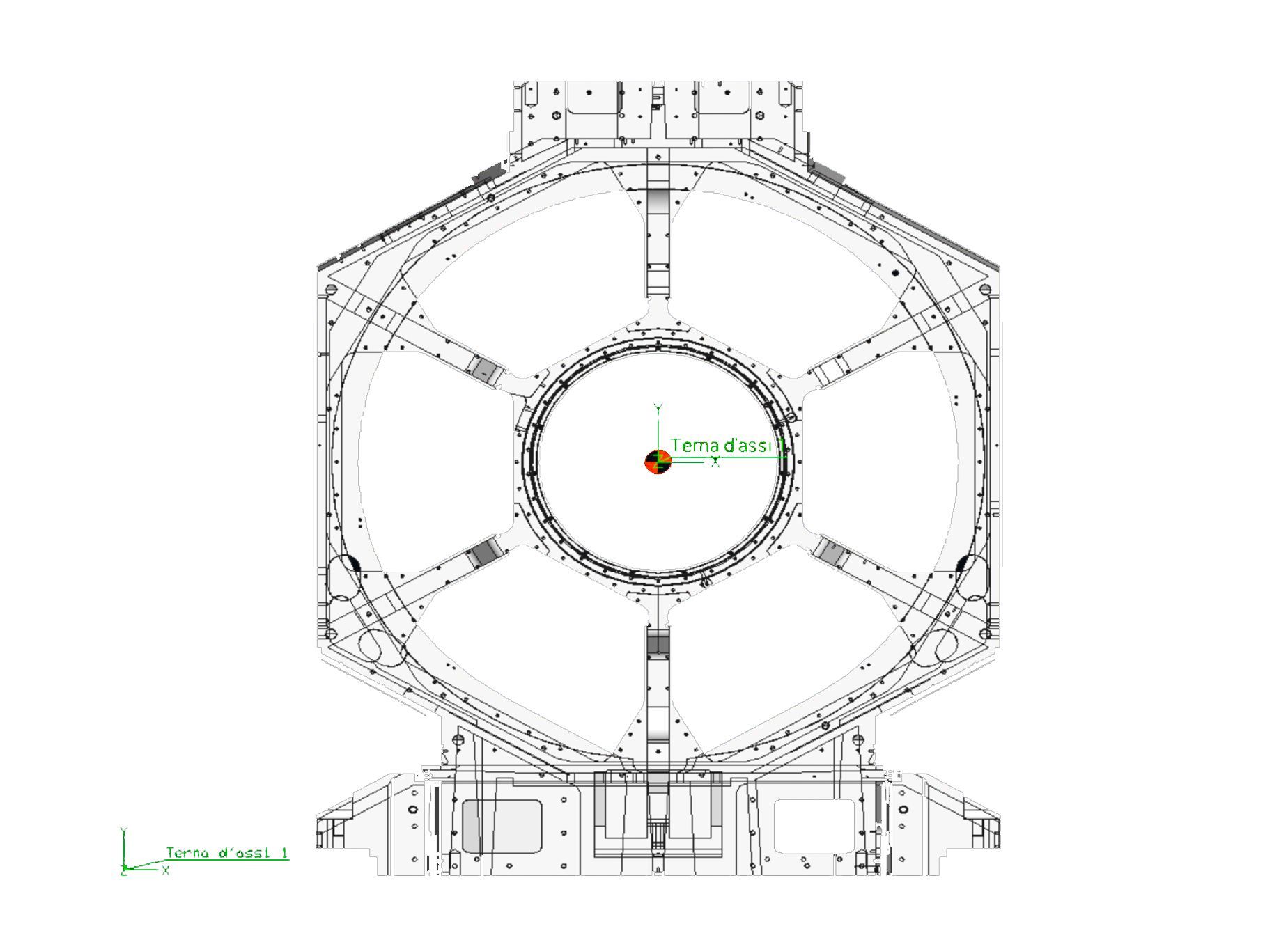

The Precision Machining Division is the qualified partner for small and large-scale precision machining work. High quality standards and high precision are achieved through solid know-how, sometimes by providing intelligent and/or alternative solutions to develop and optimize processes. DCS offers assembly, boring, drilling, milling, welding, and laser cutting services.